Mash welder

Product Introduction

Spot welding machine series:DTN-P-1/2-L

DN:Recruitment frequency spot welding machine

P:Rated capacity

1/2:1,Said lower arm for bare copper bar;2,Said a general arm

L:Arm deep dimensions, namely, arm length size

For example: the rated capacity of 100 kva, lower arm for bare copper bar, arm deep size is 500 mm spot welder is expressed as the DN - 100-1-5 00

Main Features:

>>A stable body structure

>>Second conductive part of the insulation, can avoid iron assisted with or under the seat installed when the welding workpieces produced insulation part of the short-circuit accident.

>>Can be arbitrarily adjust the pressure electrode speed, slow down the impact of the pressure on the welded object. Also reduces the noise during welding.

>>With low impedance transformer design, the two loop adopts high quality conductive material, reducing friction. Get a small input to obtain a larger welding current.

>>15 welding procedures can be stored, different welding specifications can be stored in different welding procedures, very convenient and smooth implementation of accurate welding of different parts.

>>The two feedback loop is provided, which can make up the welding current and the two discharge operation mode. Greatly improve the stability of welding, special materials can be used for preheating or tempering treatment.

>>Operating interface using digital tube or liquid crystal display, clear, clear and intuitive.

>>Is widely used in iron wire hardware, household appliances manufacturing, sheet metal processing, microelectronics and other fields.

TECHNICAL PARAMETER :

| Project | Rated capacity | Input voltage | Rated power | Largest short Current road | Load Continuous rate | Biggest Add pressure | Electrode trip | Deep size among arms | Cooling The amount of water | Weight | Electrode Size | Weldability | ||

| Electrode tip | Electrode holder | ARM | Two stitch welding low carbon steel | |||||||||||

| Model/unit | KVA | V | Hz | KA | % | N | mm | mm | L/min | Kg | mm | mm | mm | mm |

| DN-25-1-500 | 25 | 380 | 50 | 12000 | 20 | 3000 | 45 | 500 | 3 | 230 | ¢16 | ¢25ⅹ180 | ¢54ⅹ150 | 2.0+2.0 |

| DN-40-10-500 | 40 | 380 | 50 | 14000 | 20 | 3000 | 45 | 500 | 3 | 250 | ¢16 | ¢25ⅹ180 | ¢54ⅹ150 | 3.0+3.0 |

| DN-80-1-500 | 80 | 380 | 50 | 22000 | 20 | 4800 | 45 | 500 | 4 | 380 | ¢25 | ¢32ⅹ200 | ¢69ⅹ180 | 4.0+4.0 |

| DN-100-1-500 | 100 | 380 | 50 | 26000 | 20 | 4800 | 45 | 500 | 4 | 400 | ¢25 | ¢32ⅹ200 | ¢69ⅹ180 | 5.0+5.0 |

| DN-25-2-500 | 25 | 380 | 50 | 12000 | 20 | 3000 | 45 | 500 | 3 | 240 | ¢16 | ¢25ⅹ180 | ¢54ⅹ150 | 2.0+2.0 |

| DN-40-2-500 | 40 | 380 | 50 | 14000 | 20 | 3000 | 45 | 500 | 3 | 260 | ¢16 | ¢25ⅹ180 | ¢54ⅹ150 | 3.0+3.0 |

| DN-63-2-500 | 63 | 380 | 50 | 20000 | 20 | 4800 | 45 | 500 | 4 | 370 | ¢25 | ¢32ⅹ200 | ¢69ⅹ180 | 3.0+3.0 |

| DN-80-2-500 | 80 | 380 | 50 | 22000 | 20 | 4800 | 45 | 500 | 4 | 390 | ¢25 | ¢32ⅹ200 | ¢69ⅹ180 | 4.0+4.0 |

| DN-100-2-500 | 100 | 380 | 50 | 26000 | 20 | 4800 | 45 | 500 | 4 | 410 | ¢25 | ¢32ⅹ200 | ¢69ⅹ180 | 5.0+5.0 |

Note: the above data are for reference only

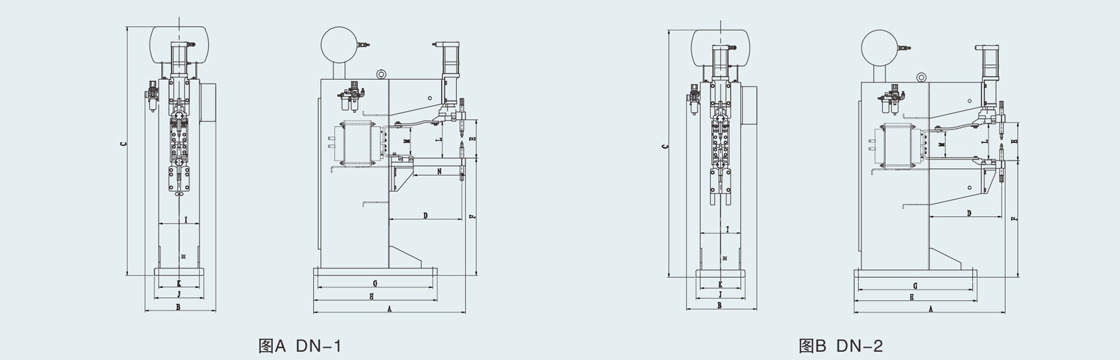

Dimensions:

| Model/project | A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| DN-25-1-500 | 1040 | 485 | 1712 | 500 | 265 | 805 | 790 | 850 | 280 | 340 | 280 | 255 | 215 | 355 |

| DN-40-10-500 | 1040 | 485 | 1712 | 500 | 265 | 805 | 790 | 850 | 280 | 340 | 280 | 255 | 215 | 355 |

| DN-80-1-500 | 1182 | 580 | 1812 | 500 | 280 | 840 | 1030 | 1080 | 350 | 410 | 340 | 270 | 220 | 310 |

| DN-100-1-500 | 1182 | 580 | 1812 | 500 | 280 | 840 | 1030 | 1080 | 350 | 410 | 340 | 270 | 220 | 310 |

| DN-25-2-500 | 1040 | 485 | 1712 | 500 | 265 | 805 | 790 | 850 | 350 | 340 | 260 | 245 | 190 | — |

| DN-40-2-500 | 1040 | 485 | 1712 | 500 | 265 | 805 | 790 | 850 | 280 | 340 | 260 | 245 | 190 | — |

| DN-63-2-500 | 1182 | 580 | 1812 | 500 | 250 | 865 | 1030 | 1080 | 280 | 410 | 340 | 240 | 220 | — |

| DN-80-2-500 | 1182 | 580 | 1812 | 500 | 250 | 865 | 1030 | 1080 | 350 | 410 | 340 | 240 | 220 | — |

| DN-100-2-500 | 1182 | 580 | 1812 | 500 | 250 | 865 | 1030 | 1080 | 350 | 410 | 340 | 240 | 220 | — |

(mm) note: the above data are for reference only

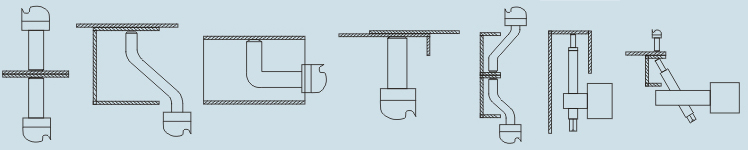

For welding form: