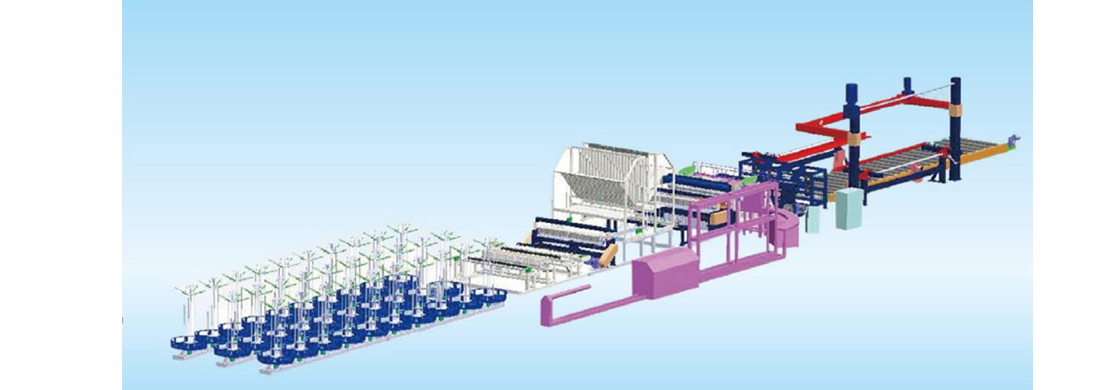

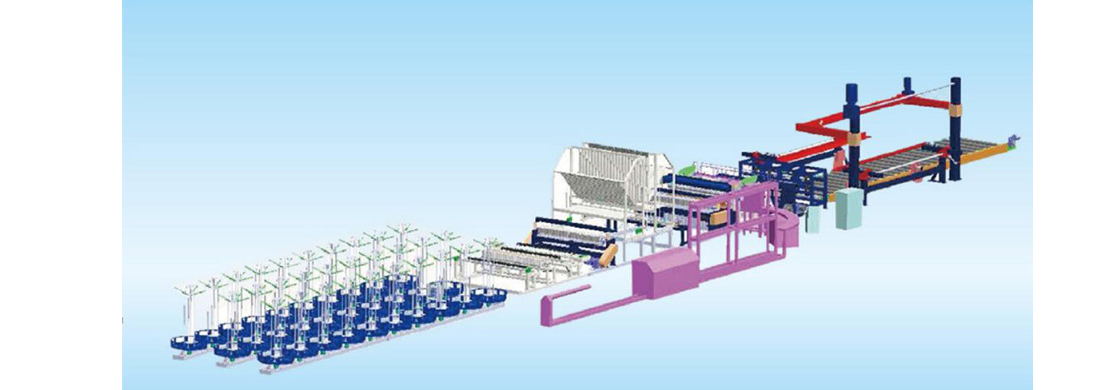

Steel fabric production line

Product Introduction

Product Features:

◆Steel bar straightening mechanism: longitudinal bars are straightened by preform through straightening mechanism, with high degree of automation and high production efficiency;

◆ Furring strips straightening and blanking mechanism: furring strips are straightened directly by preform through straightening mechanism and then delivered to the blanking mechanism, with high degree of automation;

◆ Longitudinal bar stepping mechanism: PLC+ Touch screen+ Servo motor control, accurate product welding and small error;

◆ Welding mainframe: the mainframe is firm and reliable, beautiful and decent; the mainframe is equipped with several 100KVA AC transformers; which can realize one-off welding of wire meshes and improve the welding efficiency;

◆ This production line can control any cylinder welding action and adapt to wire meshes with multiple specifications. The good cooling effect reduces the welding calorification and improves the equipment quality;

◆ Unloading mechanism: meshes which have been welded are taken out by unloading mechanism for piling so as to improve the degree of automation for this equipment and save labors;

◆ Cutting mechanism: automatic cutting according to desirable lengths of wire meshes;

◆ Roller conveying mechanism: meshes which have been piled are conveyed to the lifting area to avoid manual handling and improve the degree of automation;

◆ Inspection system: furring strips are set with in-situ inspection to avoid any welding omission and ensure the quality of meshes;

◆ Electrical control system: various electrical elements are controlled by touch screen and PLC, so as to reasonably arrange welding time, control welding actions, ensure welding efficiency and improve welding accuracy.

Main Technical Parameters:

Power supply | 380V 50Hz |

Number of power | Three phase four cable |

Load duration rate | 20% |

Air source pressure | 0.6-0.8L/min |

Cooling liquid flow | 40-80L/min |

Cooling liquid | ≤30℃ |

Maximum welding | Φ12+Φ12mm |

Interval of | Diameter of steel barØ8-Ø12mm:≥100mm(increase by |

Diameter of steel barØ4-Ø6mm:≥50mm(increase by | |

Interval of furring | ≥50mm stepless adjustable |

Diameter of steel bar | Φ4-12mm |

Feeding mode | coils material auto feeding |

Unloading mode | Unloaded by unloading machine |

Maximum welding | 50-90 rows/min |

Design Concept:

The special fully-automatic steel bar mesh welding production line is mainly used to weld special meshes such as building mesh guardrail mesh and so on with specifications of welding materials and meshes as follows

1. Material specifications: 4-12mm round steel or twisted steel.

2. Mesh specifications: interval of furring strips: ≥50mm stepless adjustable; interval of longitudinal bars: 50mm increasing.

With the rise of material prices labor and production costs it is especially important to improve the degree of automation for this equipment.

In order to resolve the problems above our company has specially designed and developed steel bar wielding to improve the production efficiency and save costs.