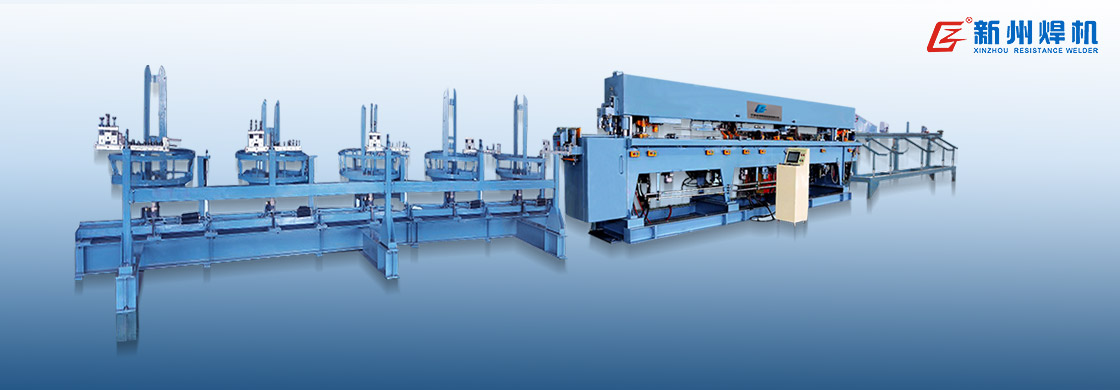

XHJ-350

Product Introduction

This equipment provides a special for steel truss production line equipment, mainly processing truss welding welding machine. Main structure:

1) feeding mechanism (2) straightening mechanism (3) the host (including welding) 4. The blanking device 5. 6. Hydraulic system cooling system 7. Control system and other parts. As shown, the device has the advantages of reasonable structure, beautiful appearance and easy handling.

Product Features:

1, equipment for the production of a wide range of: A, truss high or low range value B, the size of the bar diameter: winding 8-12mm, Xiaxian 6-12mm, brace 4-8mm.

2, production and use adjustment convenient: steel truss welding production line host using the whole frame, the whole electric up and down adjustment, meet the needs of different steel truss welding.

3, the whole production line structure is compact, covers an area of small, beautiful appearance.

4, power consumption Province: A, adjust the straight part of no power consumption, by the oil cylinder pull straight; B, the whole work in addition to three transformer welding and hydraulic station motor power consumption, the other part is not power consumption.

5, the wave spacing of reinforced steel truss can be adjusted, without the need of two artificial shear 190-210mm.

6, general steel welding without the need to oxidation treatment (can be adapted to cold rolling and hot rolling two kinds of steel welding)

7, the scope of application of this equipment: steel truss floor deck, PC precast concrete components, railway sleeper rail and other industries.

Main technical parameters:

Rated power | 3*250KW |

Power source | 380V 50Hz\ |

Phase number | 3phase 4cable |

Duty cycle | 20% |

Air pressure | 0.6-0.8Pa |

Coolant flow | >150L/min |

Coolant temperature | ≤30℃ |

Dimension | 39.4m*4.4m*3.3m |

Oil pressure | 7-11MPa |

Height of gider | Straight pediform70-350mm Bend pediform70-330mm |

Section spacing | 190-210mm adjustable (without blanking) |

Assist bar dia | φ4-φ8mm |

Upper bar dia | φ8-φ12mm |

Max.speed | 13m/min |

Lower bar dia | φ6-φ12mm |