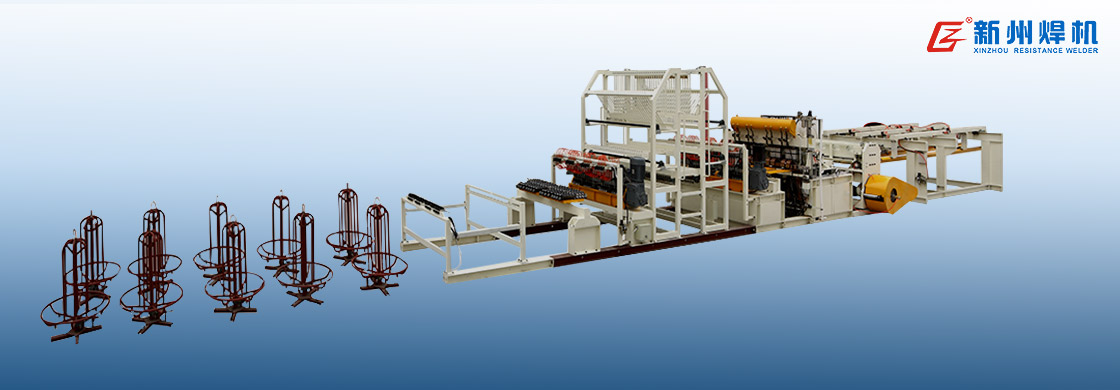

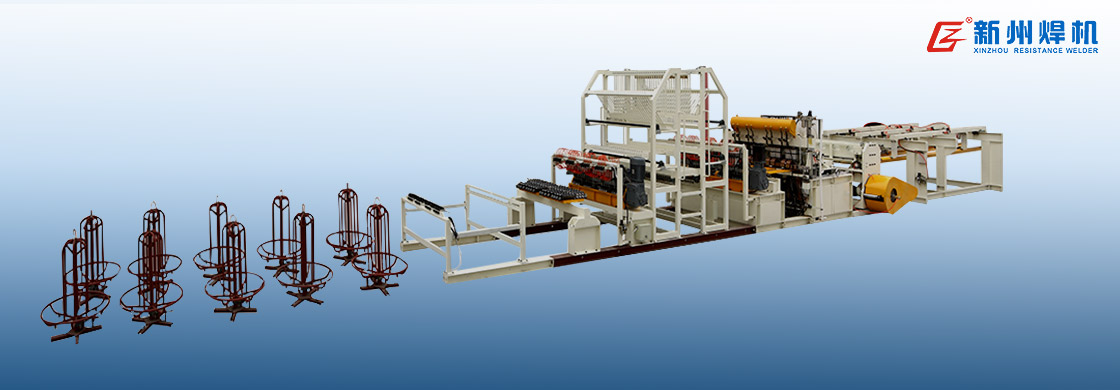

Autoclaved aerated plate production line

Product Introduction

Product Features:

◆ With high production efficiency, two meshes can be welded simultaneously;

◆ The complete welder is controlled by human-machine interface and PLC programming controller,with high degree of automation;

◆ This welder can be used to weld many materials with wide adaptability, such as hot-rolled ribbed bar, cold-rolled ribbed bar, hot-rolled plain bar,cold-rolled plain bar and so on;

◆ One or time-based welding is adopted with great flexibility according to user’s electric capacity;

◆ The machine set is designed with a discerptible structure in order for specification adjustment and maintenance;

◆ Welding systems, such as transformer, upper and lower electrodes of controllable silicon and so on, are cooled forcibly by water and equipped with a flow protection device so that the machine set works reliably and continuously;

◆ Stepless adjustable pneumatic welding system pressure can fast respond any change of steel bar specifications;

◆ Welding pressure is uniform and accordant to ensure the quality of all welding spots;

◆ Longitudinal bars are straightened by round preforms through straightening mechanism without straightening device otherwise equipped;

◆ The unique lifting mechanism can break away from the electrode during dragging meshes to ensure the service lifetime of electrode and reduce the operation expense;

◆ Furring strips blanking device adopts a stepping motor for automatic feeding to relieve the labor intensity and improve the efficiency;

◆ Imported digital servo motor system can ensure the accuracy of mesh size;

◆ Longitudinal mesh size can be changed by screen input to adapt to any change of multi-specification engineering meshes.

◆ A magnetic swinging mechanism is equipped at the blanking place of furring strips in order for fast blanking speed and high production efficiency;

◆ An in-situ device is equipped at the electrode to ensure the reliable and accurate blanking of furring strips;

◆ The unique design is favorable to conveniently, flexibly and fast replace steel bars and steel meshes.

Main Technical Parameters:

Power supply | 380V 50Hz |

Number of power phases | Three phase four cable |

Load duration rate | 20% |

Air source pressure | 0.6-0.8MPa |

Cooling liquid flow | 40-60L/min |

Cooling liquid temperature | ≤30℃ |

Maximum welding capacity | Φ6+Φ8 |

Interval of longitudinal bars | 50mm(increase by every 50mm) |

Interval of furring strips | ≥25mm stepless adjustable |

Diameter of steel bar | Ø6-Ø8 (longitudinal bar: Φ4-8mm, furring strips: |

Feeding mode | Longitudinal bar: preform; furring strips: vertical stripe |

Unloading mode | Unloaded by unloading machine |

Maximum welding velocity | 95 rows/min (interval: 50) |

Rated power | 4 x150KVA |

Design Concept:

With the use of steel bar meshes in the building industry, the demands for meshes rise increasingly, which is a challenge for production efficiency of meshes. In order to resolve this difficulty, our company has developed an automatic steel bar mesh welder. Key R&D contents: longitudinal bars are directly straightened and welded by round preforms; fast feeding of furring strips.

Objective: production automation of steel bar meshes.