Resistance welding equipment

Product Introduction

Point convex welder series:DTN-P-1/2-L

DTN:Pneumatic power frequency communication point convex welder

P:rated capacity

1/2:1,Said lower arm isn't adjustable;2,Said lower arm is adjustable

L:Arm deep dimensions, namely, arm length size

For example: the rated capacity of 80 kva, a regulation under the arm, arm size is 350 mm deep points (convex) welder is expressed as DTN-80-1-350

Main Features:

>> Stability of the fuselage structure

>> Second conductive part of the insulation on the way, can avoid the complementary with iron filings or producing insulation installed when welding under short circuit accident.

>> With upper and lower electrode using auxiliary schedule pressure mode, improve welding when the maneuverability and versatility.

>> Pressurized electrode speed can be adjusted arbitrarily, slow down the impact to the welded object when the pressure. Also reduces the noise when welding.

>> USES low impedance transformer design, two back to the way the high quality of conductive materials, reduce the internal friction. Got little input gain greater welding current.

>> Can be stored 15 welding procedure, different welding specification can be stored in different welding procedures, is very convenient, accurate welding successfully achieve different artifacts.

>> Equipped with secondary feedback loop, sustainable make up the welding current, two discharge working mode. Greatly enhance the stability of welding, and special materials for preheating or tempering process.

>> Interface using digital tube or LCD display, clear, clear and intuitive.

>> Widely used in wire hardware, household appliances manufacturing, sheet metal processing and manufacturing, microelectronics and other fields.

TECHNICAL PARAMETER:

| Project | Rated capacity | Rated primary voltage | Rated power | Largest short Current road | Load the Renewal rate | Biggest Add pressure | Electrode stroke | Deep boom Between the size | Cooling The amount of water | Weight | Electrode Size | Weldability | ||||

| Work Envelope | Electrode travel | Electrode tip | Electrode holder | ARM | Projection welding machine | Low carbon steel Two stitch welding | ||||||||||

| Type of unit | KVA | V | Hz | KA | % | N | mm | mm | mm | L/min | Kg | mm | mm | mm | mm | mm |

| DTN-25-350 | 25 | 380 | 50 | 15 | 20 | 3000 | 30 | 70 | 350ⅹ230 | 3 | 220 | ¢16 | ¢25ⅹ180 | ¢54ⅹ150 | 100ⅹ120 | 2.0+2.0 |

| DTN-40-350 | 40 | 380 | 50 | 18 | 20 | 3000 | 30 | 70 | 350ⅹ230 | 3 | 240 | ¢16 | ¢25ⅹ180 | ¢54ⅹ150 | 100ⅹ120 | 3.0+3.0 |

| DTN-80-1-350 | 80 | 380 | 50 | 28 | 20 | 6000 | 30 | 70 | 350ⅹ250 | 4 | 420 | ¢25 | ¢32ⅹ200 | ¢69ⅹ180 | 120ⅹ124 | 4.0+4.0 |

| DTN-100-1-350 | 100 | 380 | 50 | 33 | 20 | 6000 | 30 | 70 | 350ⅹ250 | 4 | 430 | ¢25 | ¢32ⅹ200 | ¢69ⅹ180 | 120ⅹ124 | 5.0+5.0 |

| DTN-150-1-350 | 150 | 380 | 50 | 38 | 20 | 12000 | 30 | 70 | 350ⅹ270 | 6 | 700 | ¢25 | ¢32ⅹ200 | ¢73ⅹ210 | 170ⅹ170 | 6.0+6.0 |

| DTN-200-1-350 | 200 | 380 | 50 | 43 | 20 | 12000 | 30 | 70 | 350ⅹ270 | 6 | 730 | ¢25 | ¢32ⅹ200 | ¢73ⅹ210 | 170ⅹ170 | 6.0+6.0 |

| DTN-63-2-400 | 63 | 380 | 50 | 25 | 20 | 7900 | 30 | 70 | 400ⅹ200∽300 | 4 | 420 | ¢25 | ¢32ⅹ200 | ¢73ⅹ210 | 170ⅹ170 | 3.0+3.0 |

| DTN-80-2-400 | 80 | 380 | 50 | 28 | 20 | 7900 | 30 | 70 | 400ⅹ200∽300 | 4 | 440 | ¢25 | ¢32ⅹ200 | ¢73ⅹ210 | 170ⅹ170 | 4.0+4.0 |

| DTN-100-2-400 | 100 | 380 | 50 | 33 | 20 | 7900 | 30 | 70 | 400ⅹ200∽300 | 4 | 450 | ¢25 | ¢32ⅹ200 | ¢73ⅹ210 | 170ⅹ170 | 5.0+5.0 |

| DTN-150-2-400 | 150 | 380 | 50 | 38 | 20 | 12000 | 30 | 70 | 400ⅹ200∽300 | 6 | 720 | ¢25 | ¢32ⅹ200 | ¢73ⅹ210 | 170ⅹ170 | 6.0+6.0 |

| DTN-200-2-400 | 200 | 380 | 50 | 43 | 20 | 12000 | 30 | 70 | 400ⅹ200∽300 | 6 | 750 | ¢25 | ¢32ⅹ200 | ¢73ⅹ210 | 170ⅹ170 | 6.0+6.0 |

Note: the above data are for reference only

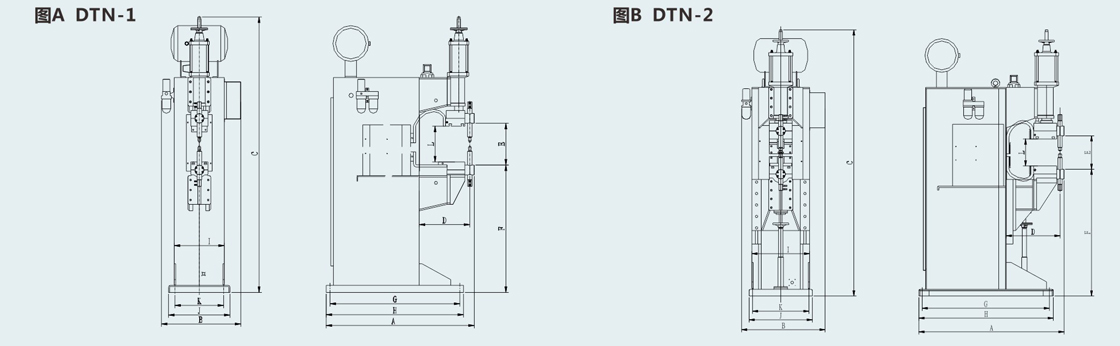

Dimensions:

| Model/project | A | B | C | D | E | F | G | H | I | J | K | L |

| DTN-25-1-350 | 895 | 465 | 1790 | 350 | 270 | 810 | 790 | 850 | 280 | 340 | 260 | 230 |

| DTN-40-1-350 | 895 | 465 | 1790 | 350 | 270 | 810 | 790 | 850 | 280 | 340 | 260 | 230 |

| DTN-80-1-350 | 1045 | 555 | 1965 | 350 | 290 | 890 | 900 | 960 | 350 | 410 | 360 | 250 |

| DTN-100-1-350 | 1045 | 555 | 1965 | 350 | 290 | 890 | 900 | 960 | 350 | 410 | 360 | 250 |

| DTN-150-1-350 | 1030 | 635 | 2030 | 350 | 320 | 820 | 950 | 1000 | 430 | 470 | 420 | 270 |

| DTN-200-1-350 | 1030 | 635 | 2030 | 350 | 320 | 820 | 950 | 1000 | 430 | 470 | 420 | 270 |

| DTN-63-2-400 | 1080 | 635 | 2020 | 400 | 260-360 | 930-830 | 950 | 1000 | 430 | 470 | 420 | 210-310 |

| DTN-80-2-400 | 1080 | 635 | 2020 | 400 | 260-360 | 930-830 | 950 | 1000 | 430 | 470 | 420 | 210-310 |

| DTN-100-2-400 | 1080 | 635 | 2020 | 400 | 260-360 | 930-830 | 950 | 1000 | 430 | 470 | 420 | 210-310 |

| DTN-150-2-400 | 1080 | 635 | 2020 | 400 | 250-350 | 890-790 | 950 | 1000 | 430 | 470 | 420 | 200-300 |

| DTN-200-2-400 | 1080 | 635 | 2020 | 400 | 250-350 | 890-790 | 950 | 1000 | 430 | 470 | 420 | 200-300 |

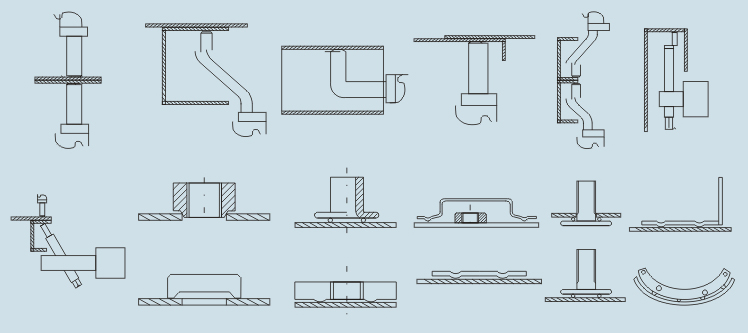

For welding form: