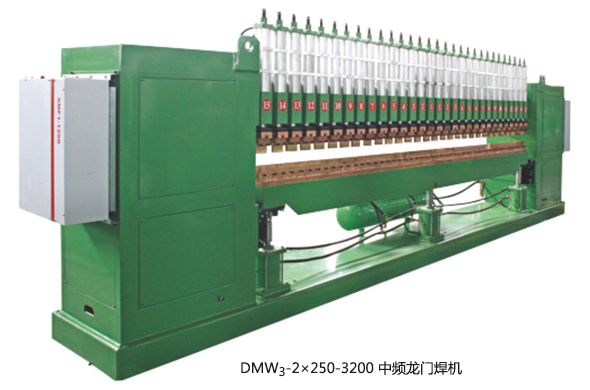

Various industries special welding machine

Product Introduction

Main Features:

>>Using intermediate frequency inverter dc square wave output, the welding heat concentration, solder joint is symmetrical. For non-ferrous metal materials and some welding welding materials is particularly suitable for hard, stable welding process, welding quality significantly improved, rapidly improve the production efficiency, also enlarge the using range of the equipment.

>>Medium frequency inverter power supply using the welding transformer, small size and large output energy, greatly reducing the weight of the core material, plus the transformer secondary circuits of rectifier diodes to convert electrical energy into dc power supply welding, improve the secondary loop inductance value, to prevent a lot of energy losses, thereby reducing the cost of production.

>>Controlled by microcomputer, it can store multiple sets of welding specification, and the user can edit a cylinder by sequence and a cylinder number and corresponding welding specification, in order to realize the welding of different products.

>>USES the high quality steel welded together one-piece superwide gantry frame, 45 # reinforced beams under annealing treatment after welding, small elastic deformation and no deformation, base Key hand USES the steel plate overall bending parts and weld reinforcement stress, ensure that the entire fuselage in welding cylinder deformation brought by the press at the same time, also because of the fuselage when preventing welding dislocation caused by the instability of the product, and so on and so forth.

Main Parameter:

| Rated Power | 2*250KVA |

| Power Supply | 380V 50Hz |

| Power phase number | Three-phase |

| Duty cycle | 20% |

| Air pressure | 0.6-0.8MPa |

| Coolant pressure | 0.3MPa |

| Coolant Temperature | ≤30℃ |

| Equipment reference outline dimensions | 8000*5670*1910(mm) |

| Effective weld width | 3200mm |

Design Concept:

Compared with the previous general gantry welding machine the device adopts the mid-frequency inverter dc power supply welding transformer by the existing grid frequency 50 hz to 1000 hz save energy reduce the production cost; Improve power because of the child make the load balance of the power supply device the fluctuation of power grid and the pressure drop of stronger adaptability intermediate frequency when adjusting the welding current 20 times faster than the traditional technology greatly improve production efficiency. Largest welding width of 3200 mm 30 groups of homemade cylinder can be independent action in order to realize the welding of different products increase the practical performance of the device.

Because the welding is simple fast nice smooth welding products solder joint even and firm is widely applied in the metal mesh shelves guardrail products such as semi-automatic welding.